What is the Best Wood Glue

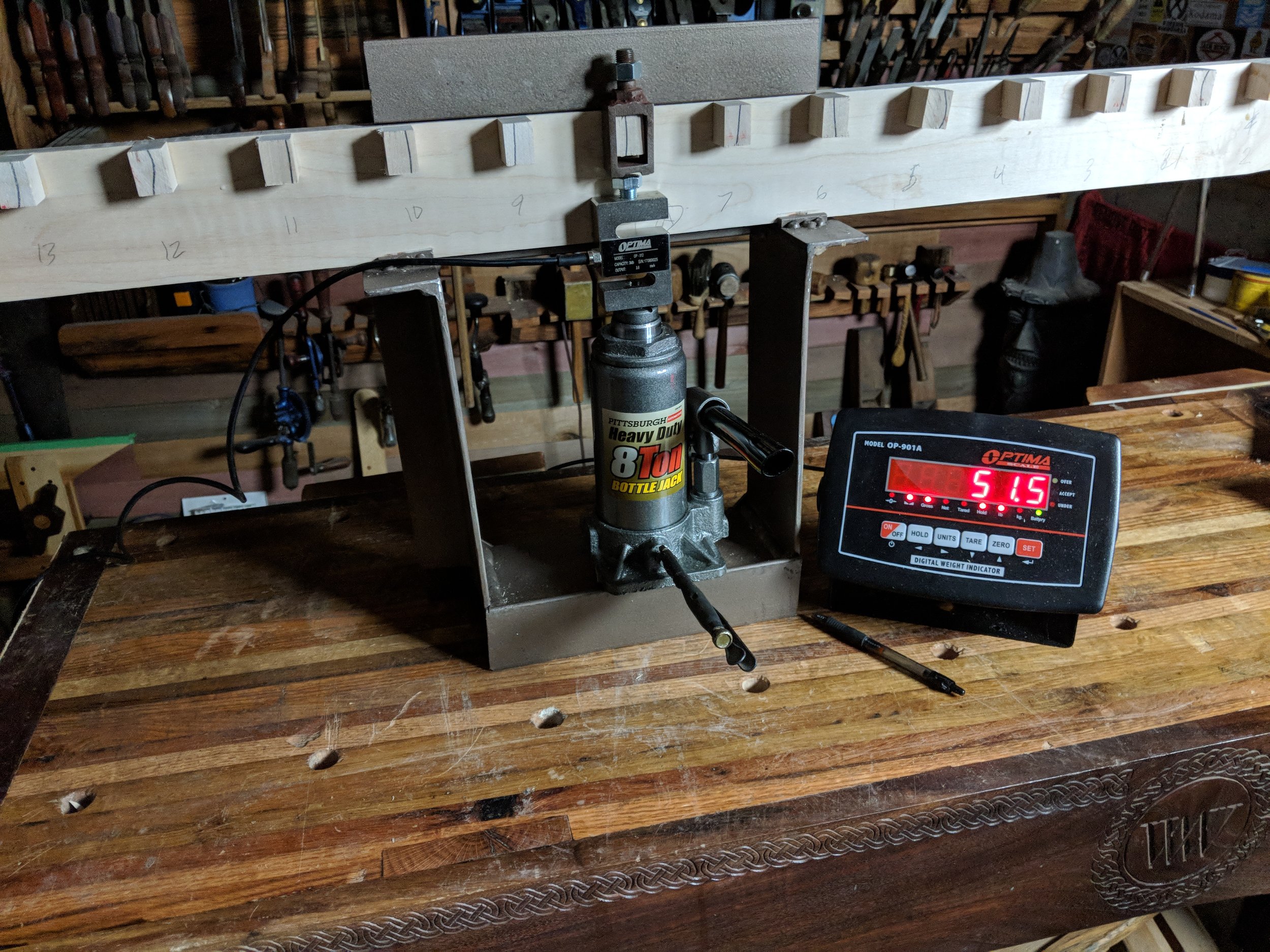

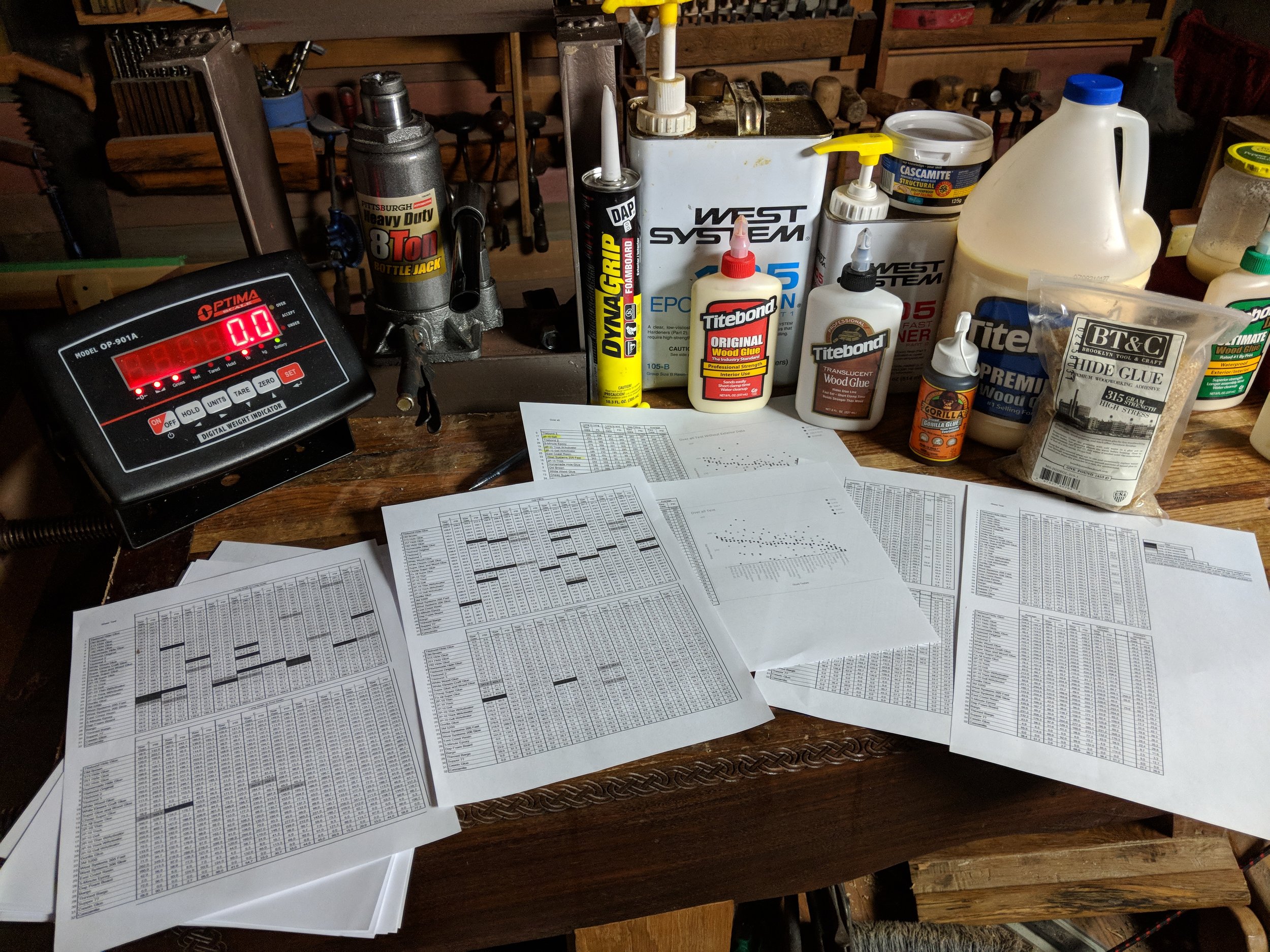

What is the best Wood glue? This wasn't the question that started this test off, but it soon became the goal of the whole test. Initially, I just wanted to know is there any benefit to using dry hide glue over one of the liquid choices? but since I'm already doing a glue test I might as well throw in a couple of the PVAs and see how those do, and in that case I might as well test epoxy, and the list began to grow from there. In there end, there was a total 32 glues pitted against each other to find out which was the best choice for one of four different situations. Long grain to long grain, long grain to end grain, gap-filling, and exterior conditions. Each glue would be tested 10 times in each of these four scenarios. All the data would be collected not by using simple dumbbell weights but by using a calibrated load cell to test the actual breaking strength of every single block of wood. What was originally going to be a test in one afternoon with a set of lifting weights ended up taking over 2 months and over $1,000 in materials and testing supplies. All that being said, I was really interested to see if any of my assumptions stood up to the rigors of an actual test.

Here is the list of all the glue's tested as well as the load cell used in the test.

Load Cell Used: https://amzn.to/2JEXrzn

Cell Reader: https://amzn.to/2vbVjw2

Glues in the test

Titebond hide glue, https://amzn.to/2vbHopJ

Old Brown, https://amzn.to/2IRwN53

315 hide glue, https://amzn.to/2ISepJk

251 hide glue, https://amzn.to/2JI50Fz

192 hide glue, https://amzn.to/2IUjRLJ

Homemade hide glue, https://www.youtube.com/watch?v=1ucmtNoKcgg&list=UUbMtJOly6TpO5MQQnNwkCHg

Titebond Original https://amzn.to/2HeRkDN

Titebond II, https://amzn.to/2HxZKng

Titebond III, https://amzn.to/2IOl1Zp

White wood glue, https://amzn.to/2GVpfC6

White Elmer’s craft glue, https://amzn.to/2vb9hyh

Super glue and wood Glue, (2P10 Thick and Titebond II)

Cheap Super Glue, https://amzn.to/2HwMLCe

Fix All Super Glue https://amzn.to/2Hj83Wh

2P-10 Thin, https://amzn.to/2ITSmSF

2P-10 Thick, https://amzn.to/2ITSmSF

2P-10 Gel, https://amzn.to/2ITSmSF

2P-10 Thin W/Activator, https://amzn.to/2ITSmSF

2P-10 Thick W/Activator, https://amzn.to/2ITSmSF

2P-10 Gel W/Activator, https://amzn.to/2ITSmSF

Gorilla Glue, https://amzn.to/2Hy9jCL

3M 5200, https://amzn.to/2vbrsUk

West systems 205 fast, https://amzn.to/2IQXtmv

West systems 206 Slow, https://amzn.to/2qwwPI3

east coast resin, https://amzn.to/2HyaPVf

5-minute epoxy, https://amzn.to/2EIpWZv

Dap Dynagrip foamboard, https://amzn.to/2GUCKO7

Barge, https://amzn.to/2EJzD9L

Thinned barge, https://amzn.to/2GX10za

Super 77, https://amzn.to/2HzNh2D

Casein Glue, https://www.youtube.com/watch?v=KhA4XrykpmQ

Cascamite, https://amzn.to/2GVqql0

For detailed information on how the test was conducted you can watch this video. https://www.youtube.com/watch?v=ZbxIpMUl_5A

What is the best Wood Glue Data

Many of the results were not that surprising. In most cases epoxies and PVA glues did very well. I was not expecting the contact cement to do very well and indeed they failed most tests. There were a few pieces of information that were extremely surprising to me. Here all list 5 things I learned from this test. If you want to see full detail with all of the data here is a link to the spreadsheet with all of the fun geeky numbers.

https://docs.google.com/spreadsheets/d/1GAZrhrtJPi8-iqPRVfqgOgf7RTg8Vqmen6OKJ4Ae6_I/edit?usp=sharing

CA Glues Used

#1. Super glue is surprisingly resilient

In the long grain to end grain test, the gap filling test, and the exterior test, the super glues or cyanoacrylate (CA) glues did extremely well. In many cases, they beat out the standard epoxies and PVA glues. There was a strong correlation between the thickness of the CA glue to the strength of its bond. The thinner the glue was the weaker the strength, but with the thick gel CA glues actually work very well as a gap-filling or end grain glue. The glues were also tested with activator to see if that changed the strength of the glue. Most of the time it did not. The thick gel CA the activator did harm the strength of the glue. Though more tests are needed to find out why for sure, I believe it has something to do with not allowing the gel enough time to soak into the wood before it was activated. I am intrigued to see if CA glues maintain their strength over time. Further testing needs to be done, but that will probably be the next glue test to be started.

Gap Filling Glue?

#2. Polyurethane glues are not for gap-filling

When I first got started in hand tool woodworking, I built a bench and the joints were not as clean as they should be. So I was told I should use gorilla glue or another polyurethane glue to fill the gaps in the joints. This seems to make sense and tends to be the common knowledge answer to gap filling in less than perfect joints. I fully expected the Gorilla Glue to hold up very well filling a large gap, but I was extremely surprised. Not only did the Gorilla Glue fail early, but it was consistently at the bottom of list of glue is used for gap-filling. You would be far better off using a thick or gel CA glue to fill a gap than polyurethane. The only thing worse at gap filling is a contact cement, and that's not by much. Moral of the story, do not use Gorilla Glue to fill gaps.

Liquid vs Dry Hide Glue

#3. There's little difference between liquid hide glue and dry hide glue

One of the key things I wanted to find out in the test is the difference between liquid hide glue, such as old brown high glue and Titebond hide glue, and dry hide glues that you mix with water in a double boiler. Though there is much to be said for the fun of making your own high glue in a double boiler, the test showed that in most instances liquid hide glue did just as well if not better than their dry counterparts. The data was enough to show me that unless I really want the fun of making my own high glue, the liquid Titebond hide glue would do just perfectly as an average wood joint glue.

"Waterproof" and "Water Resistant"

#4. Titebond II and Titebond III did not stand up well in exterior conditions

Titebond III has on the label “waterproof” and Titebond II has on the label “water resistant”. In the past, if a project was to get wet I would use Titebond III to glue the joints together. All PVA glues including the Titebond series did very poorly in exterior conditions. Many of the blocks from Titebond II and Titebond III did not even make it to the test as they fell off when being carried to the testing rig. The evidence was more than enough to convince me that from now on in exterior conditions I will be using epoxy or even CA Glue rather than any of the PVA glues.

PVA Glues

#5. PVA glue is a fantastic wood glue.

One expectation I had is that PVA glues would be vastly blown away by the superiority of epoxies and other hightech glues. I was surprised that for average uses in gap-filling and long grain to long grain the pva's stood up very nicely to the far more expensive epoxies. The strength of most all PVA glues was far more than would be needed for any joint. This reaffirmed my trust in PVA and I will continue to use Titebond II as my go-to wood glue.

Conclusion

This test was designed to find out the strength of the glue regardless of the strength of the wood. Most all of the glues tested would cause the average wood to fail long before the glue would fail. So as some of the numbers are very impressive the glues tend to be far stronger than they need to be. Some of my assumptions going into the test were destroyed, but many were upheld and reaffirmed. For most all wood glue joints, PVA is a fantastic glue that will serve very well. Hide glues are a very respectable glue with several benefits other than their strength. For exterior conditions, epoxies really are worth the expense and time needed to use them. Though in the past I have laughed at the thought of using a CA glue, I will now be adding them to my normal use as legitimate wood glues.